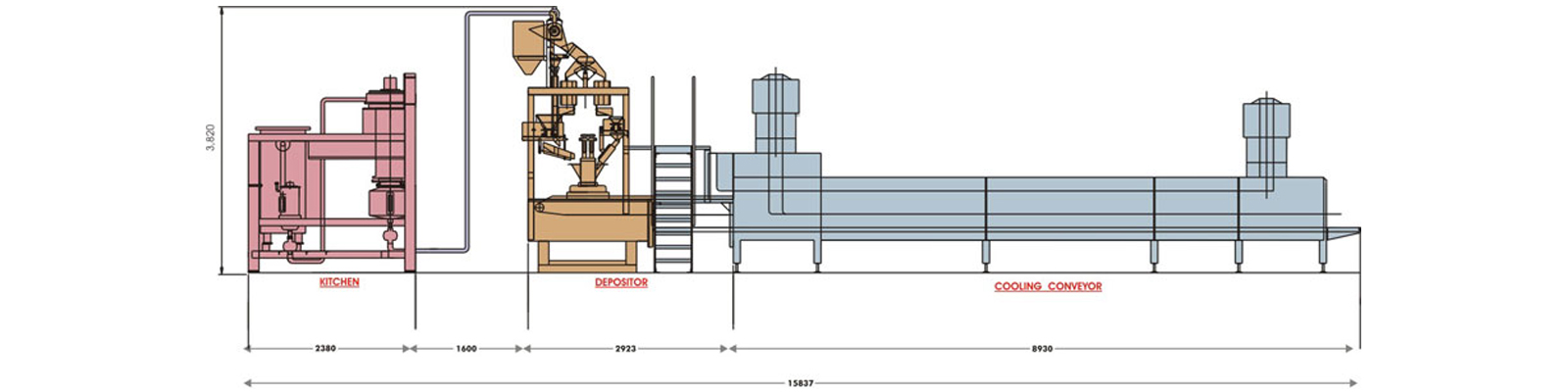

depositing

The cooked candy syrup is deposited at final moisture into rigid moulds, fitted with spring loaded ejector pins. The moulds them travels the length of the cooling tunnel and returns upside down to the ejection point, where the pins in each mould impression is depressed, ejecting the sweets. Air is blown by multiple axial fans in a contra flow direction to the mould movement for efficient cooling. The volume of air is controlled by dampers.

Makson manufactures depositing line with various capacity like one row, two rows, three rows & four rows. The capacity of each row is 250 kg/hr. with respect to size & and candy shape.

The Makson depositing is fitted with flexible silicon rubber moulds for starchless depositing of low boiled ingredients such as caramel, toffee etc. It deposits single colour, two colours and center filled “one shot products like chocolate ‘Éclairs’.